January 2014 marked the end of five years of the build. Richard is starting to sense the end of this project. He is making every effort to get her ready for the Wooden Boat Festival in Port Townsend, WA, in September of 2014.

Six years ago, on SuperBowl weekend, while we were walking along the north shore of

Flathead Lake was when he told me he wanted to build a boat!

Little did I know....

Fall, into winter of 2013 was the time for many projects to get completed.

The centerboard that had been shaped many months (or years) ago, was one such project.

Richard bought lead bird shot at the local recycling center to use as the ballast in the centerboard.

He needed 90 pounds spec'd. He calculated and had the perfect size cutout to pour in the shot, the add epoxy to keep it from shifting or moving.

Reminded me of caviar....

After drying, the thin sheet of ply was bent and epoxied on to the shaped centerboard.

The board was then glassed.....

Kind of a mess, and needing the glass trimmed.

The rasp is still the tool of choice for removing really uneven edges, prior to the fairing.

Copper coat bottom paint that was used on the centerboard case was again used.

This area will be difficult to access, once it is assembled.

Propped for painting...

A very nice (and hopefully durable) finish.

Too bad it will be underwater.

Finally the long awaited bronze portlights arrived!

We ordered 8 lights from Spartan Marine in Maine.

Very nice product and they were very profession and knowledgeable to deal with.....

We appreciate and are proud to put them in Richard's work of art.

They each weigh about 8-10 lbs.....and have an interesting matte finish.

I wasn't sure about a non-glossy finish, but after installation I am very pleased.

The first step was to place mock-up windows to check placement.

The windows in the head are slightly smaller to fit better with the cabin sides.

The patterns were checked, measured and marked prior to cutting a huge whole in the cabin side.

They actually fit....

Looking good from the inside, too.

Really adds a lot to the cabin.

The head gets one on each side.

The flange sticks perfectly through the cabin sides, and has the little drip spout area at the bottom

to help keep any trapped water from coming in when the ports are open.

They are such a nice detail when the flange rings are on...

They are all stored until ready to be permanently mounted.

While passing thru Anacortes, WA on our way back from visiting Mark

(AKA Beckon's designer)

after the Deer Harbor Wooden Boat Rendezvous on Orcas Island,

and spending time with Cecil and Janet Borel (builders of another of Mark's boats- Janetess)

we happened into a wonderful nautical "junk" shop.

It contains new, used and all sorts of consignment stuff.

An overwhelming amount of stuff to browse through....

Jane luckily grabbed this sad looking manual windlass and realized it worked very easily.

Of course, we did our research on-line quickly, and consulted with others.....a few hundred dollars vs thousands was a great deal, IF the windlass was the model with the heavy gears inside

(and not the chain drive model).

So....since the store owner reassured us that we could return it if we weren't happy with it,

we bought it and proceeded to the nearest auto parts store....

there we got an appropriate sized wrench and proceeded to disassemble the windlass enough for Richard to stick his fingers into the grease filled, solid packed inside.....no chain! But gick!

All of this while trying to keep all the grease off the upholstery of the back of my SUV....

Needless to say, the windlass made the trip back to m

Montana for a good rehab.....

The outside was very rough, but the insides were great, once the solid packed grease was removed.

Richard disassembled it in prep for a new Powder coating.....

Nice bronze parts with no significant wear to the gypsy.

After buffing the bronze and reassembling the windlass with it's $100 powder coat...

she looks like new and will be a nice addition to our fore deck.

Glad to find the heavy old thing, since Jane's dream off an electric windlass was definitely being squashed by the electrical load issue...

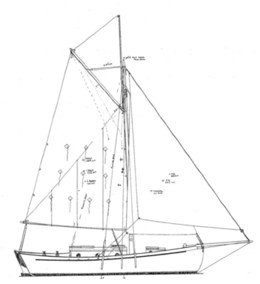

Richard had many discussions with Mark regarding the wooden mast design.

And of course he decided on the theoretically stronger, but more difficult to build "coopered" style.

Some planning and intricate jigs were needed to obtain the different thicknesses of the walls up the mast and changes in outside dimensions from deck level down to keel and up to tip.

The forty foot long mast table is now becoming mandatory.

Pieces were scarfed to create the needed length, with the scarfs at different levels for strength.

Luckily, Jon Derry (trained in wooden boat building) was willing to help with the jigs

and knowledge of the process.

Lots of milling, before even getting to the set up......

Jon placed different sized spacers at each section to accommodate the taper during the glue up.

Beautifully tight grain!

Straps were tightened as clamps to maintain the round during gluing. The little white twine just holds the tightening stick from unwinding. Simple but very effective.

At the bottom, where the mast hits the keel, Richard decided to replace some of the interior wood for strength. He decided the wiring will not be running all the way down, but exiting the mast just inside the cabin ceiling.

Hard to get a picture of all the tapers....

Taper can easily be seen here at the top.

Quick ties and shims are used for keeping the round....it is being glued in two sections so that it can be opened for placing the wiring......

It is now a noted fact, Duct tape does NOT work for holding the tightening sticks from spinning.....

He went down to the shop after a couple hours to find the tape all 'popped'......luckily it was cool and the epoxy wasn't curing quickly.

......back to using all manner of things as clamps and holders....

Looks pretty primitive but effective!

This is a pic of what we are shooting for....a beautiful traditional mast.....

Here is what it looks like when the unglued areas are removed.

A nice trough for the wires.

Hard to get a pic, but this shows where the wiring channel reduces below

the point where it will enter the cabin top.

The top has a nice taper too.

Wire for nav lights, antennas, deck lights were all spec'd.

These little cable clams provide a water proof opening for the wire to exit the mast.

Really don't want any water inside to start rot.

Richard decided to suspend conduit on slings made of cut strapping, epoxied in place for support and to keep things quiet. The mast is now awaiting a final glue up.....exit points for the wiring have been measured and drilled. The mast will be rounded after the final gluing.

The final shape of the transom hung rudder was determined after careful consideration

and ruling out of a trim tab.

All glued up, the shaping and tapering begins.

The areas to shape have been drawn on to wood.

Of course, the hand eating grinder is the tool of choice.

The tailing edge is thinned down dramatically.

Such intricate traditional shapes to promote the water flow.

The narrow thick upper area will get bright wood cheeks applied.

A little propping to see how it works.

Richard drew on the prop aperture cutout.

More cutting and fairing......

With a little help from Gus....

Fairing compound used to get that totally smooth surface.

Designing the cheeks and cutting the top section away to create the hole for the tiller to slip into....

More and more and more fairing.....

He had forgotten how much "fun" fairing is.....

Finally glassing...

With more trimming of the drips and fairing....

The cheeks are finished and varnished.

And the smooth rudder is given a coat of paint.....

Roll and tip for the perfect finish.....sanding between coats.

Lots of sanding dust on the poor tired guy!

The traditional swooped cut-out is about 2-3" above DWL.

The gray primer on the hull shows the water line prior to final painting.

After tossing around pouring the lead keel vs having it done.....read 'expensive'.....

Richard has again used his friends and associates to contact a local metal worker that is up to the challenge of such a pour. Nothing like a challenge!

So....Richard has built a mold in the exact shape of the keel blank.

The blank is on the left and the mold on the right.....

Now you may rightly be concerned about the mold burning during the pour, or blowing apart!

The first concern is handled by the use of "water glass" or sodium silicate.

It is painted into the mold and dries into a glass type finish that is fire resistant.

And interestingly enough, the lead melts and pours at about 630 degrees.

Everyone says it can be done!

A solid piece of wood is placed in the centerboard slot to keep that open during the pour.

Multiple layers of ply were used to reinforce the mold.

And little legs were cut to different lengths so that when the mold is positioned on it's side it will sit in the perfect position for the mold to fill.

Lots of blocking to prevent movement......

Then bar was used to tighten and prevent moving on the top.

A pour hole was cut at the highest point, and water glassed.

Galvanized vent pipes were placed at each end (slightly lower than the center pour hole)

to facilitate the exit of air during the pour.

Finally Jane was ready mentally to attack the upholstery.....

Deciding how to proceed was half the battle.

None of the berths were rectangular....and several had frames part way up the side....yikes.

Richard graciously offered to use his scribing skills to come up with a pattern

for the top surface of the 4" thick foam for the quarter berth.

Amazing how the shape changes and gets so much bigger as the hull flares.

I knew the sewing was not an issue, just the patterning was intimidating.

The starboard settee was fairly straight forward, except for the two frames....

at least they stayed lower than the top of the 4" foam and they would disappear

with the cushions in place.

Port settee/berth needed special care to get the bottom cushion wide enough to come up

and create the queen bed when pulled out.

Then the intimidating "cutting of the foam".

I used an electric carving knife. It worked great but complex sweeping angles and bevels were kind of dicey and a struggle....Having a person to help you follow the line on the otherside from where the knife hub is, really helps.....The dog was useless......

I soon learned that the batting covers lots of un-evenness.

Laying out the fabric and foam totally took over the living room.

I traced around the actual foam to get a tight fit when completed.

Foam, fabric and dogs everywhere....oh, a cutting table would be nice!

Since my cushions were odd shaped and would not be able to be flipped,

I used Phifertex mesh type fabric for a breathable underside...

The port settee cushion had to be beveled to allow it to fit under the too low overhang.....

there are ways to compensate for everything on a boat. Besides, it's Richard's side of the bed!

Next the bedroom becomes the lay-out area for using the seam binding tape (highly recommended) and the actual sewing. I used over 50ft of plastic zipper that I ordered from Sailrite. Very easy to install pulls and very sturdy, low profile.

The office looked like an upholstery bomb exploded....storing cushions in all stages of assembly.

Really bulky....I tried to stay organized....

Each cushion was covered with batting, attached with spray glue to the foam.

I left off the batting on the undersides where the mesh fabric was to be....

Pretty good job, if I may say so.....such a relief!

And really very easy, once I got over the intimidating shaping of the foam.....

And really dresses the cabin up...

I am very pleased with the Crypton fabric that I bought on line.

A much better price than local fabric stores (even with their sale prices).

The colors really add and elegant look, and NOTHING stains the fabric....

I even tried oil and red wine! I must have spent weeks looking at fabric swatches on line.....but the company sends out fabric swatches for about a dollar, when you narrow it down.

It seems to me that it is necessary to feel the fabric to determine how comfortable it will be to rub across and lay on in a moving boat....

We have a wooden grate right at the bottom of the companionway that leads to the main bilge.

We had a sheet metal company make us a "pan" to keep stuff from falling into the bilge.

A spot to sweep dirt into and remove....I am totally into ease of cleaning!

The centerboard of the boat is not convenient when it comes to planning a table for the saloon.

Richard got his trial and error design hat on....and came up with a swing up plan.

Yes, that is him laying on the floor trying to see if it will work.

Nothing is easy in a boat!

Still a little rickety....needs some tougher hinges to get rid of the slant.

But, it gives room for getting around to get to the head...

and folds back around the centerboard case.

Richard did an awesome job of hiding the wiring up to the overhead lights.

He drilled down though the cabin sides from the port holes, ran around the inside of the hole (the white adhesive), then up through the cabin sides to the ceiling.....

Totally hidden when the port is in place....

A thin trim piece next to the frame covers the remaining wire to the light.

Attach the light....

And presto.....wire free lighting! (Thanks Don for the port hole idea!)

An incredible find for us is a local machinist/metal worker named Eric Wolfe.

Recommended by friends, he was more than willing to help us out with our bronze hardware.

He had not worked with bronze much, but after a tiny bit of research and trial he started producing beautiful bronze pieces.

He started with the pintles and gudgeons.

Incredible workmanship on the welds.

All custom made to fit.....

Whisker stay hardware.

Here are the middle pintles and gudgeons in place.

The bottom.....

The top one hides under the cheeks...

The rudder and hull get mortises for the hardware....

All the holes are pre-drilled and the area is treated with

CPES (clear penetrating epoxy sealer).

Absolutely wicked stuff that makes you remember to wear your respirator....

Really makes a beautiful transom.....

And the cheeks add so much.....

Another project for Eric was to wrap the dead eyes and create attachment for the chain plates. Richard milled the deadeyes out of two pieces of Ipe, laminated together.

Black acetal was purchased for Eric to mill the bow rollers....

The custom design bow roller turned out beautiful and strong.

Richard built the head door out of African mahogany.....

he was pushing for a curtain! Oh come on!

I found a small but heavy solid brass reproduction knob for the head door.

The center bar needed to be cut down by re-tapping the knobs. It was made for a 2 inch thick door and our door had 1" inch stiles and rails.

We made the knobs fixed and used a ball friction catch on the door.

A simple slide bolt was the only thing we could figure out for the map cabinet.

Richard figured out a way to work on the mounting of the bowsprit.

Up close and personal with the garage door....

And we needed to figure out how to trim out the front of the bulwarks....

She does have a pretty bow....

This shows how the actual bow sprit fits with the stem cut to size. A small Ipe block on top of the stem seals up the end grain.

Here is the finished bow with our "new" windlass and the

hardware and new trim in place.

We continued the caprail to the bow sprit and filled in the open area with bright work.

It really accents the front of the bulwarks and adds so understated design features.

Check out those nice bow rollers.

Richard built the handrails and worked on the appropriate placement.

He marked where the frames were inside the cabin, so as to avoid them.....

Looking nice.....

He will also put handrails on the front hatch....

He milled out the cockpit grate for Ipe.....don't worry the saw is off.

Yikes ......quite the jigsaw.

The finished product will add drainage and traction....

Some recent pictures of the fore deck....

The quarter berth with water heater and manual bilge pump.

The cockpit...

Side deck.....

Our Christmas card 2013, put together by Eloise......

Her wide angle lens really makes it look roomy...

The glamour pose on the head!

A shot of the head hardware....

Awe.....the cushions and the mahogany door really make it look finished.

Nav station/refrigerator....

A very dusty butterfly hatch......still needing hardware....

A very wooden galley...

Inside....

And out.....

We love her......

And our to faithful companions....